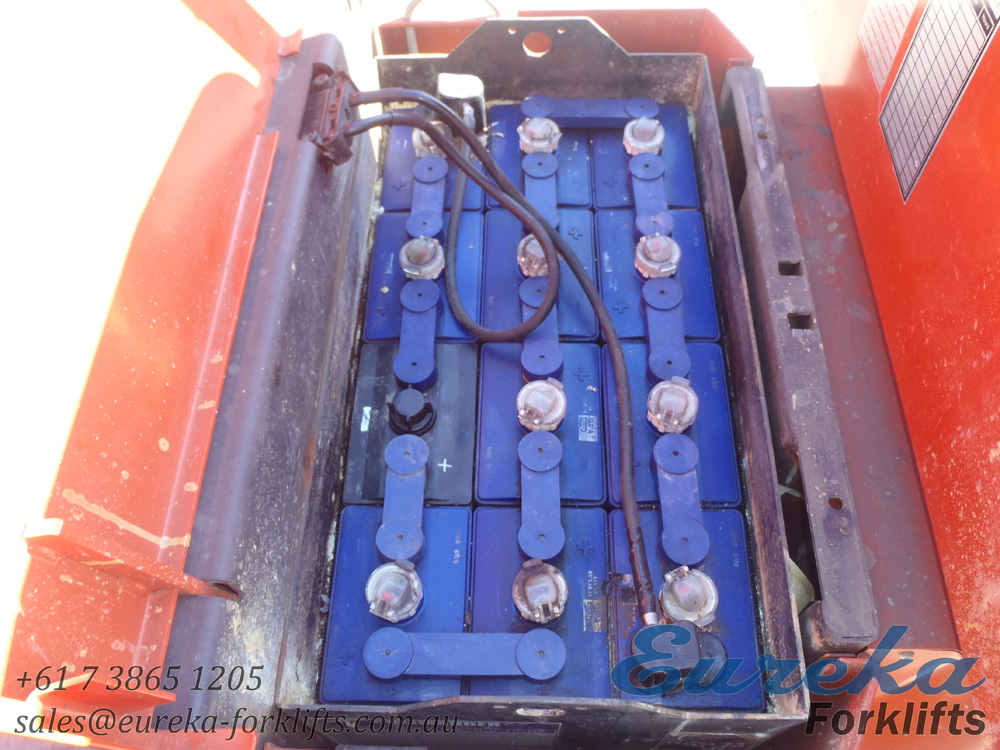

We all know that forklifts are the workhorses of warehouses and storage facilities. However, not all forklifts are created equal. Different types excel at specific tasks, from maneuvering tight aisles and stacking boxes to tackling heavy-duty jobs or heavy lifting. One question many business owners get to at one stage or another is: is a single forklift enough for your business?

Phone: (07) 3865 1205

86 Delta St, Geebung QLD 4034

PO Box 90 Geebung, Queensland, 4034